What is 3D Printing Used For?

3D printing technology was originally patented in the 1984 by American Entrepreneur William Masters. While this means that 3D printing has been around a relatively long time, it's only gained popularity relatively recently (mainly due to technological advances bringing down expenses).

New, promising methods and capabilities of 3D technologies were developed to a whole new level. However, to this day, the techniques, methods and uses are not widely known, and not everyone is aware of what 3D printing actually is. In today's article, we will try to explain in detail and in detail what 3D printing is and where it is used.

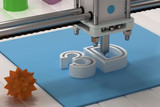

To summarize, 3D printing is a technique for manufacturing bulk products based on digital models. Regardless of the specific technology, the essence of the process is the gradual layer-by-layer reproduction of objects creating an exact copy of the digital model or original object.

In this process, a special device is used - a 3D printer that prints with certain types of materials. More details about it are written here. Other technology names are rapid prototyping or additive manufacturing. Often the phrase "additive technology" is used in the meaning of "3D technology."

Below is a demonstration of how a 3D printer can copy any object in the most minute detail to create an exact replica (besides the colour)

Use of 3D Printing

3D printing allows anyone to easily create objects of various shapes and sizes, even at home. Unlike the huge machines installed in factories, modern desktop 3D printers are compact, cheap and simple enough to start working without any serious preparation. Many have already purchased a 3D printer at home. Why is it needed? Because you can print many different things on a 3D printer.

Does your child want a new toy? Print it! Is your door handle broken? Create a new one. Custom design cup? Why not! It is often cheaper and faster to print something yourself than to buy such things in a store. Moreover, sometimes the simplest items are not on sale. For example - mounts for shelving, gears for kitchen appliances, coasters of the required size and design. The technology is already quite mature and the quality of 3D-printed products is constantly improving. It’s easy to imagine the near future when every home has a 3D printer. This may never happen, but 3D printers are available to everyone right now.

3D Printing Steps

The specific stages of 3D printing are presented below.

- Performed 3D modeling of the required object according to certain rules;

- The file with the digital model is loaded into the slicer program, in which the control code for the 3D printer is generated;

- The necessary 3D printing options are set;

- The code is recorded on a removable storage medium that connects to a 3D printer;

- The 3D model is reproduced.

The reproduction of objects occurs gradually. According to the required shape, the selected material is applied layer by layer, forming the finished product. It is worth noting that the possibilities of 3D printing are almost endless, that is, you can make anything. In some technologies, for very thin overhanging elements, supports are provided to prevent them from sagging. Naturally, this is a very simplified description of the stages of 3D printing, but they give a very clear idea of the essence of the technique.

3D Printing Technology and Methods

To reproduce various objects, various 3D printing technologies are used. They differ both in the consumables used and in the speed / accuracy of printing. There are three main types of 3D printing technology/techniques:

- Fused deposition modeling (Fused deposition modeling, FDM). One of the most common 3D printing technologies used in most desktop 3D printers and is an ideal price/quality ratio. Printing occurs by layer-by-layer filament yarn of molten plastic

- Laser stereolithography (Laser stereolithography, SLA). The formation of the object occurs due to layer-by-layer laser exposure of a liquid photopolymer resin, which hardens under the influence of radiation. One of the variations of this technology is DLP 3D printing. It uses a special projector instead of a laser. Both methods of 3D printing are used to create objects with a high degree of detail. In the case of DLP printing, speed is also an added advantage;

- Selective laser sintering (Selective laser sintering, SLS). Reproduction is performed due to the layer-by-layer melting of a special powder under the action of laser radiation. This 3D printing method is widely used in industry for the manufacture of durable metal elements.

3D printing applications

As you probably already understood, the use of 3D printing is extremely extensive. The second name of the technology - rapid prototyping - speaks for itself. In the manufacture of prototypes and models of 3D models, printing can be simply irreplaceable.

It is also a very profitable solution for small-scale production.

In the aerospace and automotive industries, 3D technologies are already in full use due to the high profitability and speed of manufacture of components.

Culinary specialists are working on the development of 3D food printers, and in medicine, 3D printing has become something of technology of the future. Using 3D Bioprinting it is planned to produce bones, organs and living tissues, and for now, implants and high-grade medicines are being printed on 3D printers.

Desktop 3D printers can be used for domestic purposes: for repair, manufacturing various household trifles and so on. And designers, fashion designers, sculptors, and artists highly value the possibilities of 3D printing and 3D modeling as an unusual way to realize their talent.

AUSTiC stocks a vast range of 3D printing supplies for many of these unique and diverse requirements.

Recent Posts

-

Best Computer Screens for Home and Office

Computer display screens, often referred to simply as monitors, have undergone a remarkable evolutio …27th Dec 2023 -

Unleashing Creativity Down Under: The Best 3D Printing Filament Options in Australia

Australia has become a hub for creativity and innovation, and 3D printing is no exception. With an …3rd Jun 2023 -

How is 3D Printing Technology enhancing the Advertising Industry?

3D printing, or additive manufacturing, is the process of using digital files to create three- dime …8th May 2023

FREE SHIPPING ON ORDER OVER $75

FREE SHIPPING ON ORDER OVER $75

LOYALTY PROGRAM

LOYALTY PROGRAM

SHIPPING WORLDWIDE

SHIPPING WORLDWIDE

72 HOURS DELIVERY PROGRAM

72 HOURS DELIVERY PROGRAM