How 3D Printing can be used for Mass Production?

Modern 3D printing uses metal and polymers: solid or flexible, hard or soft, combustible or fireproof, which are used everywhere - from manufacturing and construction, medicine and electronics to the fashion industry and even fine art.

The technical issue has not been completely resolved, the search for further optimization continues continuously, but in general terms the possibilities of 3D printing began to be outlined: modern printers can print a high-rise building, a bridge, a rocket nozzle, a titanium skeleton, an author's dress, furniture, art decor or jewellery. With the accumulated experience and new technologies, the cost of finished products is continuously reduced. The price of printers over the past five years has fallen by an order of magnitude: from tens of thousands and millions to several hundred and even tens of thousands of dollars.

The issue of practical and marketing strategy is becoming increasingly relevant: what exactly will bring the world the transition from mass to individual production? And in which industries can one seek profit?

Mass Production

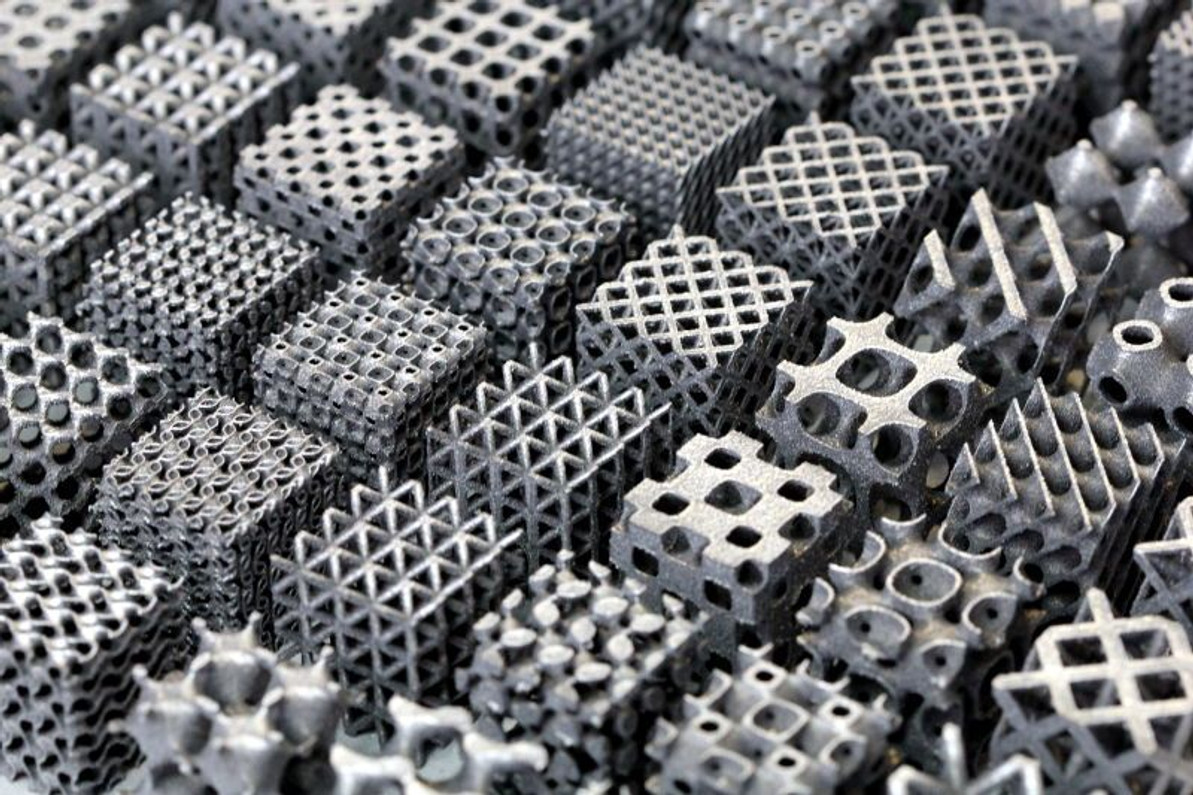

Progress in 3D printing of metal parts is progressing very fast. The advantages over outdated methods are colossal: mathematical modelling of given characteristics, instant prototyping, creation of forms previously inaccessible to machine execution, etc. Even if you don’t listen to the “apostles” and 3D printing enthusiasts, the facts speak for themselves. The world's largest manufacturers - BMW, Mercedes, Volkswagen, Ford - over the past two years have invested billions in the development of new technologies. For example, GE bought Concept Laser, Siemens announced plans for cooperation with HP and Trumpf, most major automakers announced their intention to use new technological equipment for their own production in the near future.

Recently, experts have been talking more and more about the advent of 3D printing in the aerospace industry: NASA, Boeing, Airbus, SpaceX - all are already working with printed parts for their aircraft and spacecraft. The European Aviation Safety Agency (EASA) has even certified 3D-generated parts. 3D technologies in the aerospace industry are especially in demand, because here the number of individual parts is measured in tens and hundreds. Toyota Camry consumes millions of parts, and in such volumes it is still more profitable to stamp on obsolete machine tools, another thing is rockets and planes.

Forecasts

- 3D printing will enter the mass segment over the next five years. Printing studios will appear wherever there are at least a thousand potential buyers.

- The cost of consumables will steadily decline both in the field of polymers and metal parts.

- 3D printing will soon replace small-scale production of anything, and there will be a noticeable reduction in prices due to a reduction in capital investment costs, logistics costs, storage capacity, etc.

- There will be a voluminous 3D modelling market. There will be studios calculating the form of parts and mathematical formulas of their physical characteristics. A significant part of the drawings will be in free open access, individual orders will be paid, but reasonable and feasible for a wide range of customers.

- 3D printing will create a new market for medical services, where an increasingly frequent recommendation is not the treatment or relief of symptoms, but the replacement of affected organs with new ones grown from the patient’s own cells.

- The construction industry will survive significant metamorphoses associated with mass, individual, low-cost construction. Most likely, future projects will be implemented in the concept of "new urbanism."

- US will enter this market without any noticeable lag behind the world, moreover, it will occupy a solid niche in the field of 3D modelling and development of printing software.

Recent Posts

-

Best Computer Screens for Home and Office

Computer display screens, often referred to simply as monitors, have undergone a remarkable evolutio …27th Dec 2023 -

Unleashing Creativity Down Under: The Best 3D Printing Filament Options in Australia

Australia has become a hub for creativity and innovation, and 3D printing is no exception. With an …3rd Jun 2023 -

How is 3D Printing Technology enhancing the Advertising Industry?

3D printing, or additive manufacturing, is the process of using digital files to create three- dime …8th May 2023

FREE SHIPPING ON ORDER OVER $75

FREE SHIPPING ON ORDER OVER $75

LOYALTY PROGRAM

LOYALTY PROGRAM

SHIPPING WORLDWIDE

SHIPPING WORLDWIDE

72 HOURS DELIVERY PROGRAM

72 HOURS DELIVERY PROGRAM